Tracing the origin: the R & D history of Volkswagen vacuum pump

Whenever we talk about technological innovation and progress in the automotive industry, we have to mention a core component specially tailored for Volkswagen brand cars-Volkswagen vacuum pump. Since the end of the last century, with the increasing demand for travel convenience and comfort, automobile manufacturers are facing unprecedented challenges and development opportunities. In this context, engineers began to study a technical solution that can significantly improve braking efficiency and improve vehicle safety.

After numerous tests and repeated verification, we have finally developed a popular vacuum booster (commonly known as "vacuum pump") that is now widely used. From the initial simple mechanical structure to today's integration of a number of advanced technology in one of the efficient device, this change not only represents the industry's top manufacturing level of progress, but also reflects the enterprise has always adhered to the customer-centric values oriented. Through continuous R & D investment and technological innovation, this product has become one of the most competitive competitors in the market.

Core technology: an in-depth understanding of how it works

In order to give you a more intuitive understanding of this vital component, we will explore the scientific secrets behind it. First of all, it should be clear that the so-called "vacuum pump" actually refers to a mechanical device that uses a negative pressure difference to generate strong suction. In practical applications, it is mainly responsible for providing the necessary pressure support for the air suspension system and assisting the master cylinder to complete the hydraulic transmission task.

When the driver steps on the brake pedal, the low-pressure gas generated from the engine intake manifold will be sucked into the liquid storage tank; at the same time, a local high-density flow field is formed under the action of the piston movement area. At this time, if you want to continue to maintain the original equilibrium state, you must rely on the outside to add enough fresh air molecules into the cavity to offset the vacancy phenomenon caused by the former. As a result, we can see the long and thin and curved small pipe constantly busy ...... Yes, this is the legendary "breathing effect".

Precise matching: Which Volkswagen models are suitable for

As an important part of the famous German car companies, many of Volkswagen's best-selling cars have achieved support for this configuration. Whether it is a family car or a business SUV, or an MPV multi-purpose van, you can find the corresponding suitable model for the majority of users to choose and use. For example, Passat, Magotan and other mid-level luxury cars are equipped with the latest generation version. However, compact SUVs such as Tiguan L and Tanyue X adopt a design idea that is more compact and delicate but not ineffective. As for high-performance steel cannons such as Sagittarius GLI and Golf R, they are equipped with top-level product line members to meet the demanding requirements of enthusiasts.

It is worth noting that although there are some differences between the different series, they share highly consistent basic parameter settings and excellent interchangeability characteristics. This means that even friends who come into contact with such accessories for the first time do not have to worry about incompatibility. In addition, according to past sales data, most buyers showed great satisfaction evaluation on it, believing that after the replacement, they obviously felt that the braking torque increased a lot, thus improving the overall driving stability.

Hands-on: Easy Installation Steps Guide

For those who love the DIY culture and want to solve daily maintenance problems by themselves, mastering the correct disassembly and assembly process is undoubtedly a very necessary link. The following are specific instructions on how to successfully complete a standard operation:

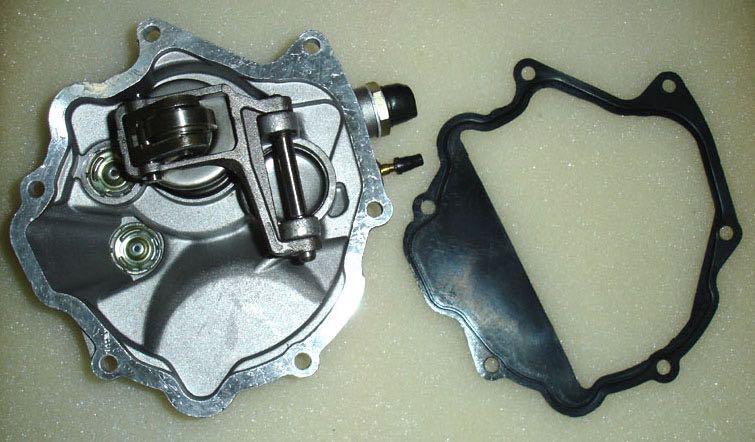

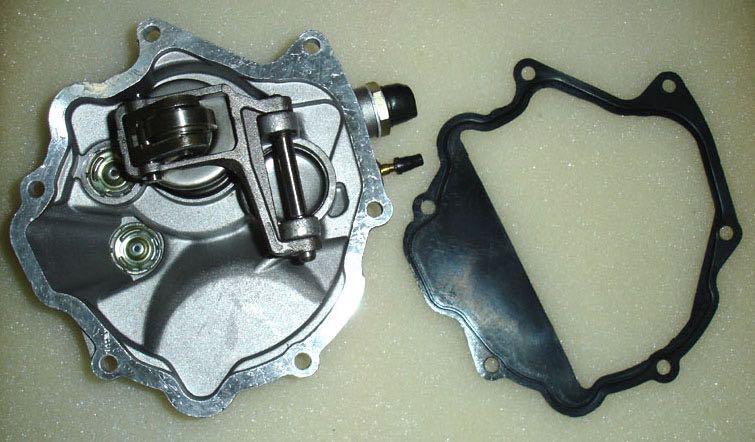

The first step, of course, is to be fully prepared in advance! After preparing relevant tools such as wrenches, screwdrivers and other basic instruments, please be sure to carefully read the tips on the attached instructions so that the subsequent operation can proceed smoothly. The next step is to remove the front cover and remove the obstacles around the engine compartment, exposing the target element located in the front position on the left.

before removing the old parts, remember to cut off the power supply to prevent accidental short circuit accident ~ then slowly loosen the fixing nut counterclockwise until it is completely detached. After all fastening points have been unfastened, carefully pull out the connecting pipeline to successfully take out the original movement. The last step is naturally to reassemble the newly bought substitutes in the reverse order ~ but before that, don't forget to check again whether each interface is tightly matched, so as to avoid potential leakage problems in the future.

Excellent Advantage: Why Choose Volkswagen Original Accessories

Making the best decision in the face of a wide range of options in the market is often not a simple matter. However, when we focus on the authentic goods produced by the official authorization, the answer seems to become clearer ~ Compared with other imitations, the latter, although the price is low, lacks the quality and after-sales service system support, and can only bear the risk and loss in case of problems.

In contrast, choosing genuine merchandise is undoubtedly a smart and sensible choice. On the one hand, they are strictly in accordance with the international ISO quality management system certification standards for production and testing, so as to ensure that each factory batch has reached the industry-leading level; on the other hand, relying on the perfect after-sales network coverage, even if far abroad can also enjoy timely and effective technical support services. Not only that, but also the professional evaluation report issued by the authoritative third-party testing organization shows that the performance in the durability test is particularly excellent, and the average life span is more than thousands of hours, far beyond the average level.

Security: Ways to extend service life

In order to get the maximum return on this investment, reasonable maintenance is also one of the key factors. Here, I 'd like to share with you some practical tips: it is very important to check the state of the sealing rubber ring regularly, and any slight crack will lead to leakage or even failure. In addition, you can apply a proper amount of lubricating oil to slow down the friction loss. At ordinary times, you should also pay attention to keeping the surrounding environment clean and tidy