A high-performance vacuum pump specially designed for Volkswagen models to ensure stable operation of the engine system. This product is made of high-quality materials, with excellent durability and reliability, effectively extend the service life. Applicable to a variety of models of Volkswagen, is the best choice for owners to maintain their cars.

Accurate Adaptation-A Power Companion Tailored for Each Volkswagen

Dive into why Volkswagen vacuum pumps stand out among many similar products. This article will detail how this key component has been precisely designed and adjusted for different years and models of Volkswagen cars to ensure perfect compatibility. Whether it is an early classic or the latest flagship version, this vacuum pump can always find the most suitable application scenario and provide unparalleled work efficiency.

Over the years, Volkswagen has continued to introduce new models, and the configuration of models in each period is very different. Our R & D team is well aware of this and took these changes into account when developing this vacuum pump. For example, in order to adapt to the smaller space layout of older models, we have specially optimized the internal structure; and for the large-size turbocharged engine launched in recent years, the flow parameters have been reset to ensure that it can be connected with the latest generation. ECU seamless docking.

Powerful power-the secret weapon that helps the engine perform at its best

Analyze the core role of the vacuum pump in the operation of the vehicle and its impact on the driving experience. When it comes to fuel economy and acceleration performance, many people tend to ignore this seemingly insignificant but vital gadget. In fact, it can not only maintain the normal pressure level of the braking system, but also assist other important functions such as exhaust gas recirculation. By comparing the differences between ordinary models and the usual use of high-quality vacuum pumps, we can intuitively feel the changes brought about by them.

Imagine this scenario: two Volkswagen Golf with the same displacement are equipped with ordinary vacuum pumps and our high-performance version driving on the road. The former may be slow to respond in an emergency due to insufficient braking force; the latter always maintains a sensitive and accurate braking effect, which not only improves safety but also reduces fuel consumption. This is a good vacuum pump brought about by the obvious improvement! In addition, under high-speed cruising conditions, cars equipped with high-level vacuum pumps have lower noise and higher ride comfort.

Quality Creates Trust-Excellent Material Selection Achieves Extraordinary Life

Focus on top-of-the-line raw materials and technical specifications selected by the manufacturer. From basic construction to fine processing, every link is strictly controlled to ensure the top quality of the product. In particular, it is mentioned that some special alloy components give the equipment higher durability, so that it can still maintain excellent performance under extreme conditions without being damaged. At the same time, some test data are listed to prove that the brand's products far exceed the industry average performance record.

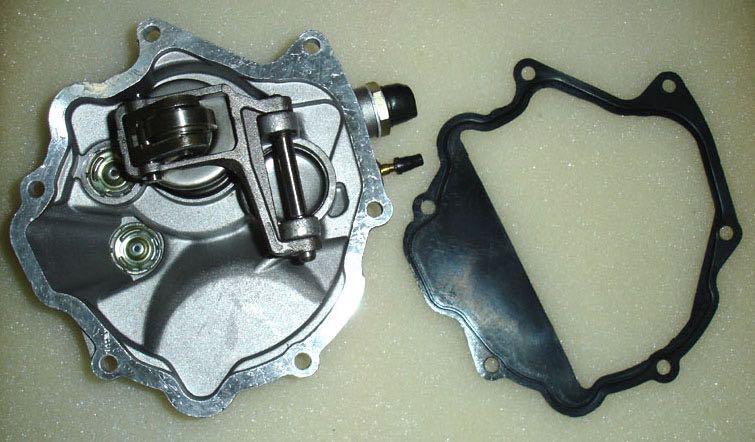

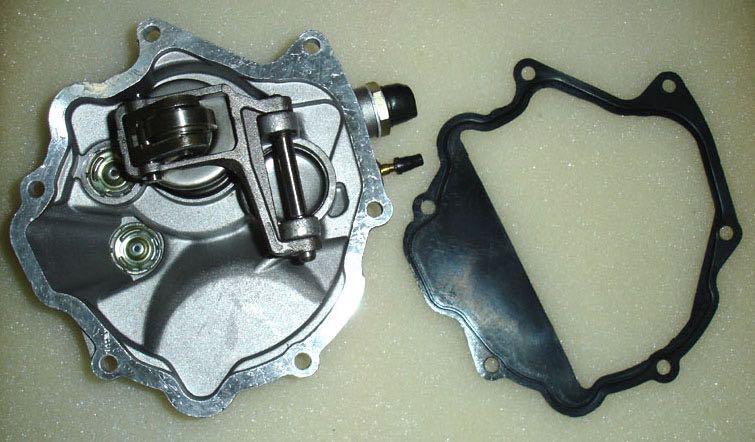

In terms of selection, we always adhere to the principle of "using only the best. The shell part is made of high-strength aluminum alloy, which is made of precision casting process. It is light in weight but extremely strong. The piston rod is forged from special stainless steel with high surface hardness and strong corrosion resistance. More importantly, all metal contact areas are coated with a nano-scale lubricating coating, which greatly reduces frictional resistance, thereby extending the overall life of the entire device. According to the professional test report issued by a third-party organization, the original accuracy can be maintained without deformation or water leakage after simulating the real road conditions for more than 100,000 kilometers.

Worry-free maintenance-Simplifying routine maintenance makes life easier

Discuss the convenience and lower cost of this vacuum pump to users. Due to the use of innovative sealing technology and self-lubricating bearing design, the frequency of regular inspection and replacement of parts is greatly reduced. This means that car owners can enjoy a long and stable driving experience without having to go to the repair shop frequently. And once a problem occurs, you can quickly find a suitable solution and obtain technical support through official channels.

Vacuum pumps in the traditional sense usually need to add grease frequently to prevent dry aging, which undoubtedly adds a lot of trouble. However, our improved new model has a built-in automatic oil seal adjustment device, which can intelligently supplement the right amount of grease according to the actual situation, completely eliminating the manual intervention step. Not only that, the new composite bearing comes with lubrication effect, even in high temperature and high pressure environment is not easy to burn card. Therefore, the majority of users can rest assured to drive their own cars everywhere.

Green Mobility-Environmental Commitment to Sustainable Development

Explains that the company follows strict environmental-friendly principles in the production and sales process. As a responsible brand, we always adhere to the low-carbon concept in the whole supply chain management, minimize resource consumption and promote circular economy mode. For example, clean energy is widely used in the production line to drive the operation of the machine; and scientific and reasonable recycling procedures are adopted in the waste treatment, so as to achieve a win-win situation of economic benefits and social responsibility.

With the increasingly serious problem of global warming, the "double carbon" strategy has become one of the common goals of all walks of life. To this end, we put energy conservation and environmental protection into the focus of consideration at the beginning of product development. First of all, the raw material collection link gives priority to the selection of recycled aluminum ingots instead of raw ore, greatly reducing the energy consumption of mining; Secondly, the introduction of solar photovoltaic panel power supply system in the assembly workshop instead of the traditional mains supply mode, saving a lot of electricity expenses every year and contributing to the earth. The most important thing is that the waste product recycling plan is gradually being implemented, aiming to build a complete closed-loop industrial chain.