What is a Volkswagen vacuum pump

Volkswagen vacuum pump is an indispensable part of the automobile brake system. Its main function is to generate a vacuum during the operation of the engine, thereby assisting the work of the brake booster, making it easier for the driver to save effort when stepping on the brake pedal. The vacuum pump is usually installed in the engine compartment, and its function is realized by belt drive or electric drive.

The working principle of vacuum pump

The working principle of the vacuum pump is relatively simple but very important. When the engine is running, the vacuum pump will draw air in the intake manifold, thereby forming a negative pressure (ie vacuum) inside the intake manifold. This negative pressure is transmitted to the brake booster, so that the booster can provide additional force when the driver depresses the brake pedal, reducing the driver's operating burden. This can not only improve the braking efficiency, but also reduce the fatigue caused by frequent braking.

The role of vacuum pump in the brake system

The function of the vacuum pump in the brake system is mainly to provide the necessary vacuum pressure to support the normal operation of the brake booster. Without the vacuum pressure provided by the vacuum pump, the brake booster will not be able to play its due auxiliary role, and the driver needs to apply more force to complete the braking action. Therefore, the vacuum pump is essential to ensure the stability and safety of the vehicle braking system.

Common faults and cause analysis

Although the vacuum pump is well-designed and durable, some common failures may still occur during long-term use. For example, the vacuum pump may leak air, resulting in insufficient vacuum pressure; loose or broken belts will also prevent the vacuum pump from working properly. In addition, wear or damage to the inside of the vacuum pump may also cause its performance to decrease. If you find that the vehicle feels heavier than usual or responds slowly when braking, there may be a problem with the vacuum pump.

How to check the status of the vacuum pump

It is very important to check the status of the vacuum pump regularly. You can check it through the following steps:

First, start the engine and observe the vacuum gauge on the instrument panel (if equipped) to confirm whether the vacuum pressure reaches the standard value. Secondly, check whether the belt of the vacuum pump is tight, whether there are cracks or wear. Finally, gently shake the vacuum pump by hand. If you feel obvious looseness or abnormal sound, you may need to further check or replace the vacuum pump.

Choose the right Volkswagen vacuum pump

Choosing the right vacuum pump is essential to ensure the safety and reliability of the vehicle. When buying, you should pay attention to the following points:

First, make sure that the selected vacuum pump is suitable for your model and year. Different models may require different types of vacuum pumps. Secondly, choose well-known brand products, the quality of these products and after-sales service is more guaranteed. Finally, check the product's certification mark, such as ISO 9001, etc., to ensure product quality.

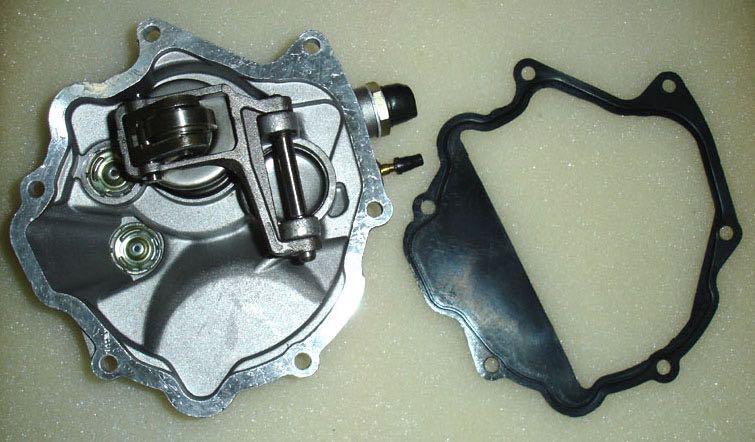

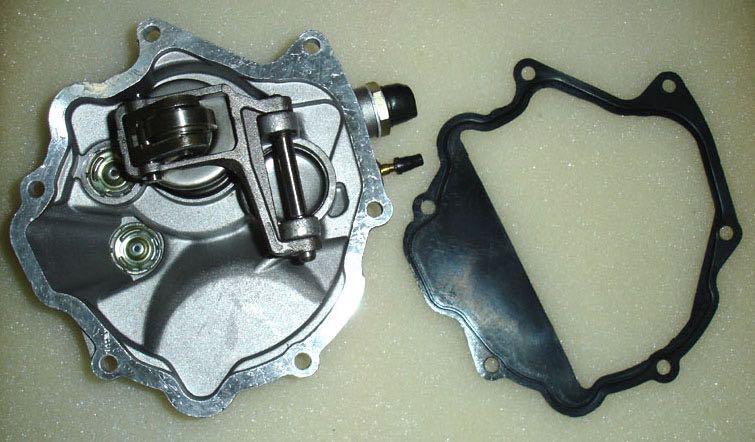

Steps to replace the vacuum pump

If you are sure you need to replace the vacuum pump, you can follow the steps below:

1. Turn off the engine and wait for it to cool down.

2. Disconnect the negative electrode of the battery to prevent short circuit.

3. Remove the old vacuum pump and note the connection method and location.

4. Install a new vacuum pump to ensure that all connections are firm and reliable.

5. Reconnect the negative electrode of the battery, start the engine and check whether the vacuum pump is working properly.

Routine maintenance and maintenance

In order to extend the service life of the vacuum pump, daily maintenance and maintenance cannot be ignored. It is recommended to check the belt tension of the vacuum pump regularly, and adjust or replace it if necessary. In addition, regular cleaning of dust and debris around the vacuum pump and keeping it clean also helps to improve its work efficiency.

Case Study: Problems Caused by Vacuum Pump Failure

A car owner reported that during a long journey, he suddenly found that the brakes became so heavy that he could hardly control the speed of the vehicle. After inspection, it was found that the belt of the vacuum pump had broken, resulting in insufficient vacuum pressure, which caused the brake booster to fail. Fortunately, the car owner stopped in time and sought professional help to avoid a serious traffic accident. This case re-emphasizes the importance of regular inspection and maintenance of vacuum pumps.

Precautions for vehicle owners and service technicians

For car owners, regular inspection of the vehicle's braking system is an important measure to ensure driving safety. Once the brake is found to be insensitive or other abnormal conditions, you should promptly contact a professional maintenance technician for inspection and maintenance. For maintenance technicians, correct diagnosis and standardized operation are the key to solve the problem. When replacing the vacuum pump, always follow the manufacturer's technical manual to ensure that each step is accurate.

FAQ

Q: Will a broken vacuum pump affect the driving of the vehicle?

Answer: Yes, a failure of the vacuum pump will cause the brake booster to fail, causing the driver to apply more force when stepping on the brakes, which will seriously affect driving safety.

Question: How to judge whether the vacuum pump is working properly?

Answer: You can judge whether the vacuum pump is working properly by checking the reading of the vacuum gauge, listening to the sound and manual detection.

Q: What should I pay attention to when replacing the vacuum pump? <